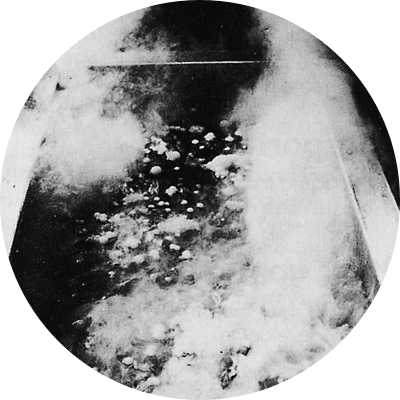

Without ALLPLAS

Hot acid solutions give off heavy corrosive vapor.

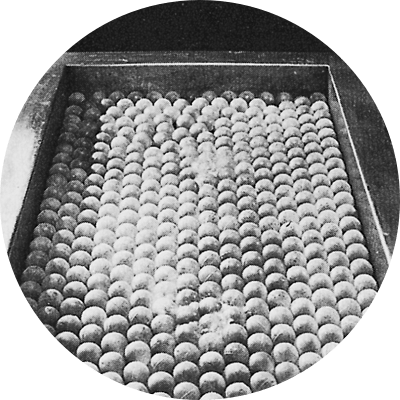

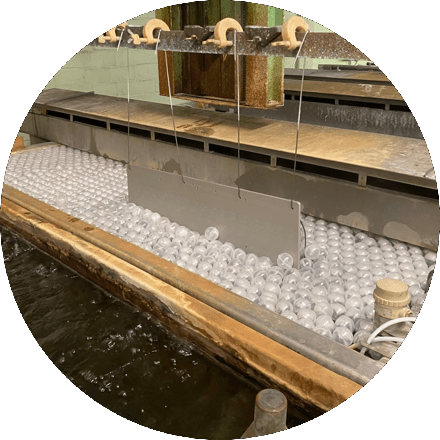

With ALLPLAS

The same tank, covered with a layer of ALLPLAS balls, gives off nearly zero vapor.

Simply and safely cover open storage container facilities, additionally saving on energy costs!

The 15 advantages

of ALLPLAS floating balls:

-

1

Saving energy – reducing costs

Save at least 50 % in costs –

Example calculation -

2

Reduction of heat losses

Single layer: up to 75 %

Double layer: up to 82 % -

3

Reduction in evaporative losses

Up to 88% reduced chemical consumption

-

4

Reduced environmental impact

due to reduced emissions

-

5

Reduced moisture absorption

from air contact

-

6

Reduced oxidation and contamination

of liquid baths

-

7

No splatter

of hot or corrosive liquids

-

8

Oxygen absorption minimized

– up to 63 % –Prevent corrosion damage

-

9

Reduced nuisance odours

up to 98 % less

-

10

Foolproof installation

The floating balls are simply poured onto the surface of the liquid

-

11

Low investment costs

compared to fixed covers

-

12

No accumulation of explosive gas concentrations

between cover and liquid surface

-

13

Significantly simpler handling

compared to fixed covers

-

14

No unnecessary operational and maintenance costs

-

15

Good accessibility

Objects can be immersed and removed without impediment at any time

Do you have an unusual application?

No problem – we are sure to find the best solution for your needs.

Application options

The plastic (PP / HDPE) floating balls can be used anywhere where liquids should be protected against evaporation and the ensuing consequences.

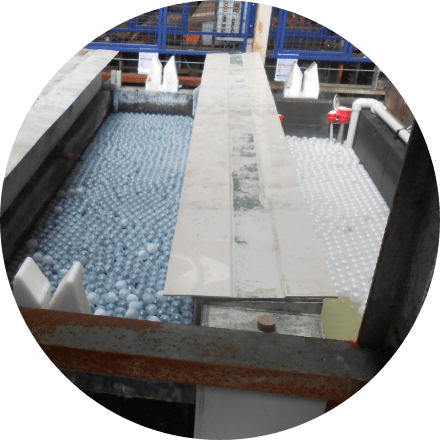

The ALLPLAS blanket system is based on the use of hollow plastic balls, which are produced using a special procedure that eliminates any seams or blowholes. There are no maintenance costs as the floating balls are simply shaken onto the liquids where they automatically arrange into a uniform layer. This procedure almost entirely covers the liquids without creating the disadvantages posed by a fixed lid. The danger of explosive carburetion due to gas concentrations between the media surface and the lid is also eliminated.

A coverage with ALLPLAS balls avoids hazardous emission and discharge of chemicals

Prevention of hydrogen evolution on the electrodes

Energy saving in electroplating at ED Metallbearbeitung GmbH, Bremen

Galvanizing, Anodizing, Metal Separation

In galvanizing processes hydrogen build-up on the electrodes creates significant problems. Expensive chemicals are delivered, the atmosphere is contaminated by toxic substances. The problems are eliminated through coverage using ALLPLAS floating balls and in addition there is a reduction in energy loss. The 45 mm PP floating ball has been proven to be highly effective in this case. The ALLPLAS coverage balls can also be used on almost all metal separation and anodizing baths.

Relief for Extraction Systems

Evaporation and steam development are almost completely eliminated on coverage with the ALLPLAS floating balls, this considerably minimises the capacity of the ventilation system for given work - in some cases ventilation can be omitted completely. As both energy consumption and maintenance have to be invoiced in the calculation of the operational costs for an extraction system, it is possible to make substantial savings. Tank heating costs can be reduced if the air circulation for the ventilation systems can be slowed down by the use of ALLPLAS blanket system.

Reduced Effect of moisture

A number of liquids absorb moisture from the air under certain atmospheric conditions. Without coverage technical disadvantages and storage problems ensue (e.g. in the case of sulphuric acid). In the “Copper Belt” in Zambia, where thousands of litres of sulphuric acid are used on a daily basis, the corrosion of huge storage tanks due to concentration changes in sulphuric acid present a serious problem. Tests conducted in this area have shown that coverage using a layer of ALLPLAS floating balls reduces the penetration of moisture from the air by 60 %.

Reduced Oxygen Transfer

ALLPLAS floating balls are used in electricity, gas, nuclear and heating plants to avoid heat loss from condensate from the return and warm water basins. Another important use: The oxygen intake is drastically reduced. A high content of dissolved oxygen causes expensive corrosion damage in boiler feed water plants, cool water containers and water reservoirs. As little as one layer coverage with 45 mm PP floating balls reduces the oxygen transfer in water by 63%.

Reduction in unpleasant odours

As little as one single layer of ALLPLAS floating balls reduces the H2S content in the air circulating above a hydrogen sulphide solution by 98.2 %! The results are practically independent from the speed of the air circulation. Practical tests and experience with ammonia, crude oil and similar substances confirm that a layer of ALLPLAS coverage balls provides a highly effective method for preventing odour emission.

Protect outdoor pools from contamination, algae formation and bird flight

Water-filled "Bird Balls" protect open liquid surfaces (water ponds, airport ponds or rainwater collection basins) from contamination, algae formation and danger from flying birds.

With a weight of 240 g per ball, the Bird Balls lie deeper in the medium than other covers – this makes them extremely resistant to strong winds (up to wind force 12) and prevents the floating balls from being blown off the medium. The black coloring also makes the Bird Balls UV-stable and weather-resistant.